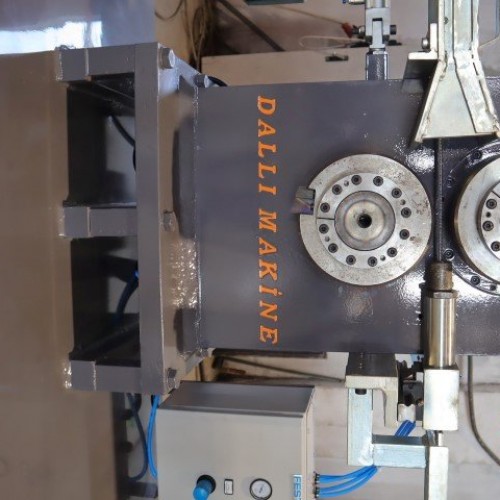

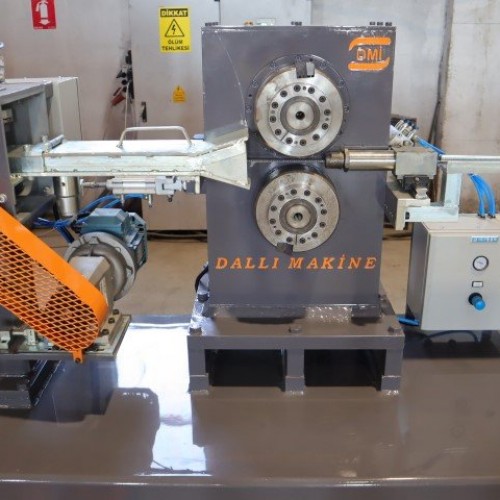

COLD ROLLING LINE FOR THE PRODUCTION OF SMOOTH AND RIBED WIRES IN BAR Ø4.5MM TO Ø12MM

.jpg)

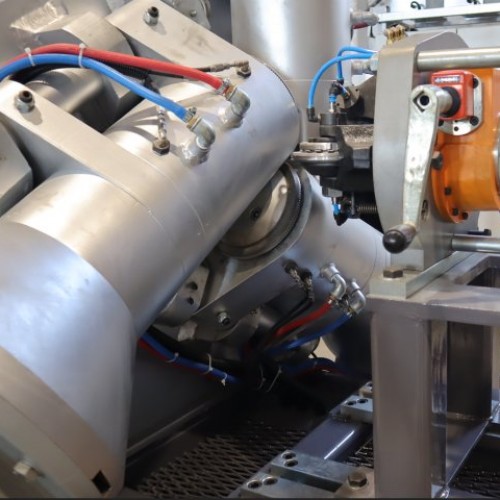

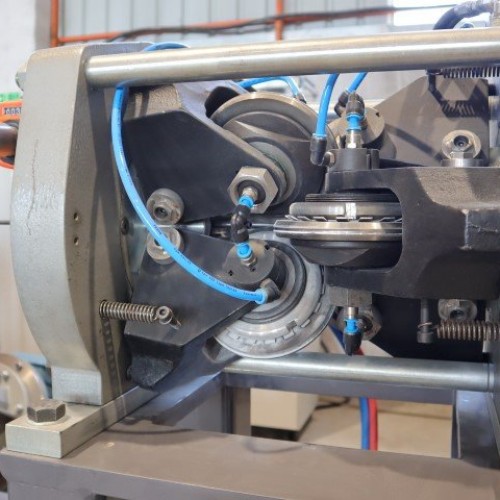

It was developed for the production of ribbed wire with 3 tungsten carbide plates directly coupled to the motors and aimed to provide lower operator interaction with lower friction contact.

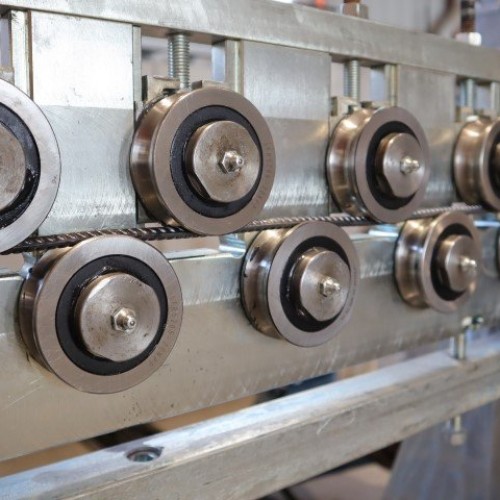

The wire is drawn and ribbed for diameter reduction, then straightening and cutting to desired length.

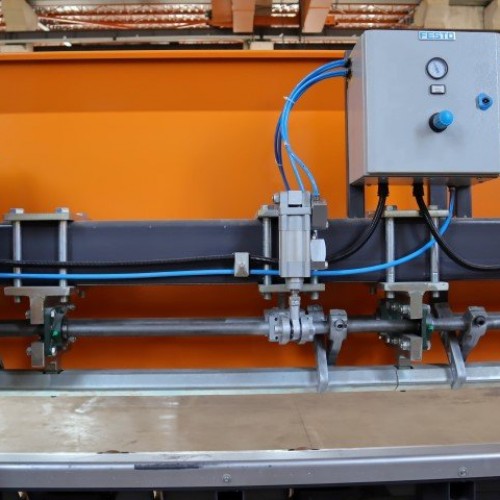

- Servo motor for flying shear cutting system designed for the continuity of production

- Easily adjustable rotary flyer straightening system

- Max cutting speed: 300 m/min

Equipped with safety equipment for operator safety, it is a high quality machine that stands out with its easy maintenance and short set-up time.

- DMI 217 Ø 5.0 – Ø 8mm (300m/min)

- DMI 400 Ø 5.0 – Ø 12mm (300m/min)

TR

TR

EN

EN